While polyurethane (PU) provides energy savings, lightness and comfort, boots made of PU tend to be longer lasting and fit for purpose.

PU is a versatile material that can solve many problems. Extremely good when it comes to flexibility, tear and abrasion resistance, it can be manipulated in various ways to create a solid and durable product. PVC, on the other hand, does not perform well in terms of abrasion or weather resistance and does not have environmental health benefits.

Boots made of lightweight and highly abrasion resistant Polyurethane are more resistant to liquids, fats, fertilizers, acids and chemicals compared to PVC. Due to the flexibility of PU, it is more convenient and comfortable than boots made of PVC.

There are other benefits to using PU instead of materials like PVC. While the PU industry supports the practice of conserving resources and minimizing the environmental and health impacts of plastics and products, polyurethanes help maintain energy sustainability.

In addition to PU being a much more durable and versatile product, the basic building block of PVC is chlorine (Cl), and chlorine production releases dioxins into the environment. This often leads to leaky PVC products that contain toxic additives. Because many of these additives are not chemically bound to the plastic, they can escape from the product, causing potential hazards to consumers.

In addition, throwing PVC into landfills poses a risk to the environment. Because flexible PVC degrades in landfills, toxic additives leach from waste, posing a problem for unlined landfills. These additives also contribute to the formation of landfill gases generated in municipal landfills.

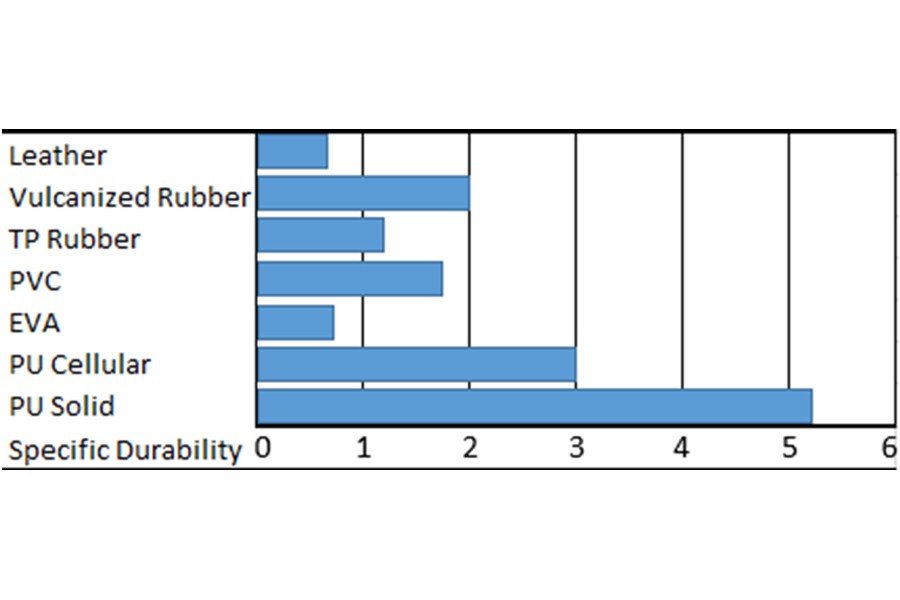

The durability comparison of PU and other materials is shown below.